If you listen closely as you walk into the integrated services area at Kitchell’s Arizona office, you’ll hear the soft whir of the company’s 3D printer hard at work. You’ll also find Steve Berry close by, Kitchell’s 3D printer authority eager to share his enthusiasm about this innovative technology. While 3D printing technology has been around since the 1980s, Berry is quick to point out that the terms “ground breaking” and “revolutionary” are really meaningful when describing how 3D printing is transforming the construction business. Improvements in technology and an increased demand have allowed 3D printers to drop in price, making them a more attractive tool, especially when it comes to integrated projects produced by highly collaborative teams, an increasingly popular construction delivery method.

As a sales tool, Kitchell’s 3D printer has paid for itself and then some. The ability to quickly print different design possibilities enables owners to essentially see their future product in the palm of their hand. Owners (and people in general) love to pick up a miniature version of their vision and turn it around, peek through openings and then envision themselves in the modeled space.

Benefits of 3D printing

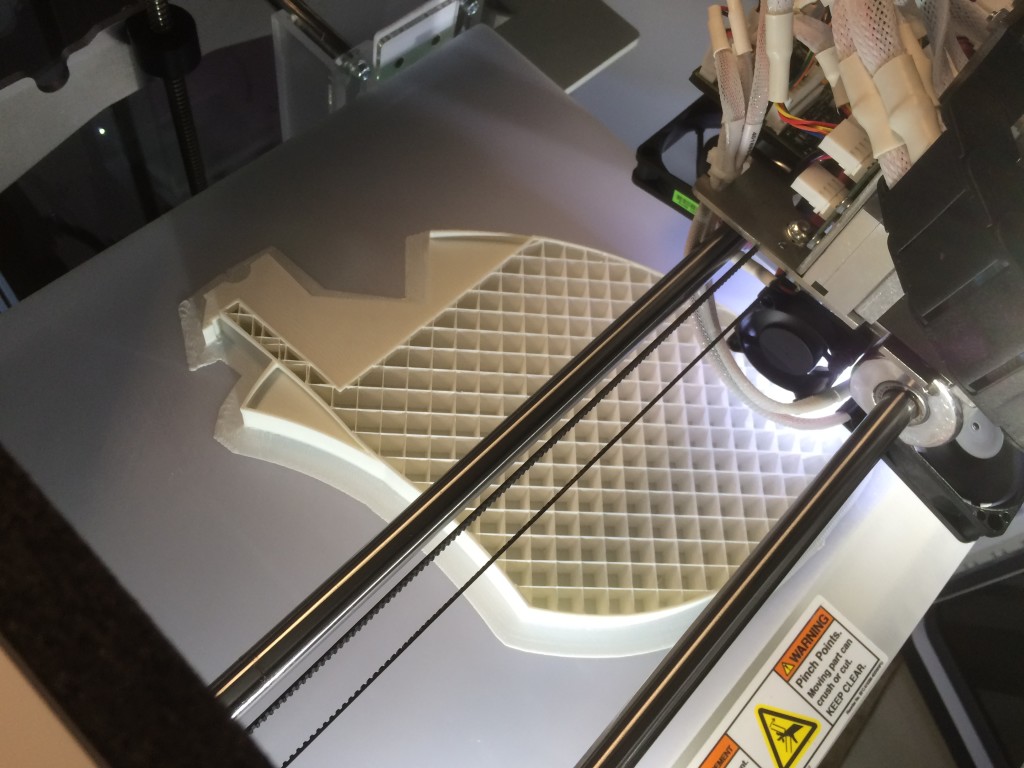

3D printing, also known as Additive Manufacturing, is a process where thin layers of warm plastic material are successfully layered up according to a digital design file, which is extracted directly from a Building Information Model (BIM). Berry shared additional ways that Kitchell is benefiting from 3D printing:

Prefabrication and 3D printing are a perfect match, as both allow faster and more accurate construction of complex items where cost is lowered and waste reduced. Kitchell is at the forefront of prefabrication, especially when economies of scale can be achieved utilizing duplicate components. Examples of facilities that can benefit are hospitals and ambulatory clinics, which typically need hundreds of the exact same exam rooms or bathrooms which require redundant framed wall components. Even complex hospital patient rooms with utility headwalls can be prefabricated and installed with significant time savings. 3D printing enables builders and designers to create precise prefabrication models that can then be easily tweaked to increase production efficiency or incorporate changes without wasting time.

Sauer and Berry both agree that the past 10 years have seen a flood of technological advancements that can make us ever better builders. We are always pondering, “What’s next on the innovation horizon, and how can we utilize the technology to bring value to our customers?”

Project Executive Clark Sauer works with a model of California Hospital Medical Center

3D printing for seamlessly linking digital and physical worlds

The ability to share digital model information between contractors, designers, engineers and owners with tangible forms of a construction project is transforming ideas to objects. Kitchell and Devenney Group Architects recently created a scaled city block of more than 20 buildings from a 3D printer to showcase three design options during an interview/work session for an expansion of California Hospital Medical Center in Los Angeles. “The owner loved the model,” said Project Executive Clark Sauer, a 35-year healthcare construction veteran. “Three tremendous benefits of the 3D-printed model were 1) The extruded plastic model wasn’t as fragile as traditional cardboard and wood models so we could all ‘pick up and play’ with the proposed building parts; 2) creating it was a fraction of the cost of traditional models; it took just days to print as compared to the hundreds of man-hours it would have taken to build a model the ‘old’ way.” Berry explained the 3D Printer can run 24 hours a day so models can be extruded and layered throughout the night (Berry actually has a webcam positioned on the model so he can check the 3D printer’s progress when it’s “working” in the wee hours).

Benefits of 3D printing

3D printing, also known as Additive Manufacturing, is a process where thin layers of warm plastic material are successfully layered up according to a digital design file, which is extracted directly from a Building Information Model (BIM). Berry shared additional ways that Kitchell is benefiting from 3D printing:

Prefabrication and 3D printing are a perfect match, as both allow faster and more accurate construction of complex items where cost is lowered and waste reduced. Kitchell is at the forefront of prefabrication, especially when economies of scale can be achieved utilizing duplicate components. Examples of facilities that can benefit are hospitals and ambulatory clinics, which typically need hundreds of the exact same exam rooms or bathrooms which require redundant framed wall components. Even complex hospital patient rooms with utility headwalls can be prefabricated and installed with significant time savings. 3D printing enables builders and designers to create precise prefabrication models that can then be easily tweaked to increase production efficiency or incorporate changes without wasting time.

Sauer and Berry both agree that the past 10 years have seen a flood of technological advancements that can make us ever better builders. We are always pondering, “What’s next on the innovation horizon, and how can we utilize the technology to bring value to our customers?”